1D Mirror

See Product Listing and Guide (PDF Download)

Features:

-

Single-axis quasi-static (point to point) MEMS Mirrors

-

Flat high quality mirrors up to 8.0 mm diameter

-

Plug and Play Development Kits and OEM Drivers/Controllers

-

Mass Production Ready Low-cost compact MEMS scanning modules

Product Applications:

-

MEMS scanning LiDAR systems

-

Laser marking and 3D printing technology

-

MEMS Mirror-based Display and Picoprojector technologySi

-

3D Tracking and Position Measurement

-

Windshield Head-Up Display (HUD) technology

-

3D Imaging for Biomedical Imaging (Medical Research and Diagnosis)

-

3D Scanning Metrology

-

Automotive (Dynamic) Laser Headlights

-

AR/VR – wearable headsets and tracking systems

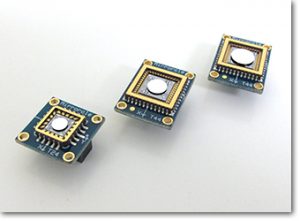

MEMS Mirrors (Gimbal-less Single Axis MEMS Mirrors)

- Gimbal-less design gives ultra-fast two-axis laser beam steering

- Large angles in point-to-point (quasi-static) or resonant mode of operation

- Variety of mirror sizes available in stock, from 0.8mm to 4.2mm (See Product Listing and Guide)

Gimbal-less Single Axis (Tip-Tilt) MEMS Mirrors

Scanning single axis (tip-tilt) MEMS mirror (or “micromirror”) is an optical beam-steering (or 1D optical scanning) technology that is used in many industries. There are several major benefits of the Mirrorcle’s tip-tilt MEMS mirror over competing products. Gimbal-less Two-Axis Scanning Micromirror Devices based on ARI-MEMS fabrication technology initially developed through research projects at the Adriatic Research Institute (“ARI”) in Berkeley, CA, provide ultra low-power and very fast optical beam scanning in two-axes. The devices deflect laser beams to optical scanning angles of up to 32° at high speeds in both axes. Compared to the large-scale galvanometer optical scanners, our devices require several orders of magnitude less driving power. Continuous full-speed operation of our electro-static actuators dissipates less than a few milliwatts of power.

MirrorcleTech devices are made entirely of single-crystal silicon, resulting in excellent repeatability and reliability. Optically flat and smooth mirrors are coated with a thin film with desired reflectivity. Larger mirrors can be bonded onto actuators for custom aperture sizes. Mirror sizes from 0.8mm to 4.2mm in diameter are currently available in stock. Sizes up to 9.0mm were successfully demonstrated in special applications. (see demonstrated on youtube)

MirrorcleTech’s MEMS micromirror technology is highly versatile and adaptable to various applications. Some devices are fabricated with somewhat generic quasi-static (point-to-point) performance specifications. Other devices are highly customized to achieve specific set of specifications, such as e.g. projection-displays.

Key Benefits

The tilt angle is analog as opposed to on-off.

See video of tip-tilt-piston movement under microscope.

This is the key differentiation with digital micromirror elements which can not be used for arbitrary-direction optical beam steering. In other words, if a tilt angle of 6.15° is required, it is simply a matter of applying the correct voltage and that angle (or any other angle) can be obtained and maintained for any length of time with nearly zero power consumption.

Point-To-Point Scanning

The devices are designed and optimized for point-to-point optical beam scanning mode of operation. A steady-state analog actuation voltage results in a steady-stage analog angle of rotation of the micromirror. There is a one-to-one correspondence of voltages and angles that is highly repeatable.

Modular Design

In order to produce devices with a different mirror size, most technologies require not only a new fabrication cycle, but in some cases complete actuator redesign. Mirrorcle Technologies is the world’s only provider of a MEMS based, customizable aperture size beam steering technology. Namely, sets of electrostatic actuators optimized for speed, angle, area footprint or resonant driving are designed and realized in a self-aligned silicon fabrication process. Metallized, ultra low-inertia single crystal mirrors made stiff and flat by a special design of silicon beams are created in a separate fabrication process. The diameter, as well as geometry of the mirror is selected by customer, in order to optimize the trade-offs between speed, beam size, and scan angle for each individual application. The mirrors are subsequently bonded to the actuators.A variety of gibmal-less two-axis actuator designs are available. The actuators lend themselves inherently to a modular design approach. Each actuator can utilize rotators of arbitrary length, arbitrarily stiff linkages, and arbitrarily positioned mechanical rotation transformers. In stock categories include 4.25mm x 4.25mm die size, 5.2mm x 5.2mm die size, 7.2mm x 7.2mm die size, and 8.0mm x 8.0mm die size. In most cases, larger die size allows better performance due to increased electrostatic force. Beyond die size other parameters are varied such as e.g. stiffness. One device series for example is designed to operate at large angles (-7.5° to +7.5° of mechanical tilt,) while another series is designed to operate at small tip-tilt angles but dramatically higher speeds (-0.8° to +0.8° of mechanical tilt).

High Speed Point-To-Point Optical Beam Scanning

The major advantage of our proprietary gimbal-less design is the capability to scan optical beams at equally high speeds in both axes. A typical device with a 0.8 mm diameter-sized micromirror achieves angular beam scanning of up to 500 rad/s and has first resonant frequency in both axes at approximately 4 kHz. Large angle step response settling times of <100 µs have been demonstrated on devices with micromirrors up to 0.8 mm in diameter. Devices with 2.0mm diameter mirrors can achieve large angle step settling times of <1ms, with first resonance of approximately 1.3 kHz.

Dynamic Mode Scanning

Devices can also operate in the dynamic, resonant mode. In this mode, low actuation voltages at frequencies near resonance result in large bi-directional optical beam angles (e.g. -16° to 16°). Resonant frequencies are in the range from several kHz up to 21 kHz and higher for MEMS display applications. Resonance depends on the actuator type (series,) and the micromirror type and diameter that is assembled with the actuator.

See Product Listing and Guide (PDF Download)

Integrated Mirror Devices:

- Mirror Sizes: 8mm, 1.2mm, 1.7mm, and 2.0mm diameter always in stock.

- Maximum tilt angle under point-to-point driving: -6° to +6° mechanical each axis, varies with design type.

- Maximum tilt angle under resonant driving: -7° to +7° mechanical

- See support page for more info

Point-to-point or Quasistatic

Single-axis MEMS Mirrors with bi-directional tilt on the X-axis:

| Actuator |

Actuator size |

Mechanical Angle [°] | Package | Integrated | Integrated | Integrated | Bonded | Bonded | Bonded | Bonded | Bonded |

| Mirror Diameter [mm] |

0.8mm |

1.0mm |

1.2mm |

0.8-1.2mm |

1.6-2.4mm |

3.0, 3.6mm |

4.2mm |

5.0mm |

|||

A1Q12.5 |

4.25mm | Tiny20.4 | – | – | V | – | – | – | – | – | |

A9S1.1 |

5.20mm |

±6° |

Tiny20.4 | V | V | V | V |

V ~750HZ Resonance (Elliptical 3.2mm x 2.0mm) |

V | V | – |

A9S2.1 |

5.20mm |

±5° |

Tiny20.4 |

V ~850HZ Resonance (Elliptical 3.2mm x 2.0mm) |

|||||||

A9Q40.1 |

5.2mm |

±4.5° |

Tiny20.4 | – | – | – | – | – |

V 2KHz, (LINE mirror 4.0mm x 1.3mm) |

||

A5L2.1 |

7.25mm |

±1° |

Tiny48.4 | V | V | V | V |

Resonant

Single-axis MEMS Mirrors with bi-directional tilt on the X-axis:

| Actuator Name | Actuator size | Mechanical Angle [°] | Package | Integrated | Integrated | Integrated | Bonded | Bonded | Bonded | Bonded | Bonded |

0.8mm |

1.0mm |

1.2mm |

0.8-1.2mm |

1.6-2.4mm |

3.0, 3.6mm |

4.2mm |

5.0mm |

||||

A1D.4

|

4.25mm |

±7.5° |

Tiny20.4 |

V 24Khz |

|||||||

A1Rx |

4.25mm |

±6° |

Tiny20.4 |

V |

V 15KHz |

– |

– |

– |

– |

– |

– |

A9Rx |

5.20mm |

±7.5° |

Tiny20.4 |

V 24Khz |

– |

V 12.5Khz Resonance |

V |

– |

– |

– |

– |

A5L2.1S |

7.25mm |

±1° |

Tiny48.4 |

– |

– |

– |

– |

V |

V |

V |

V |

See Product Listing and Guide (PDF Download)

“SensLite represents Mirrorcle products in Taiwan local market only, please contact memsmirror@senslite.com.tw for inquiry in Taiwan.

Please visit www.Mirrorcletech.com for other global sales.”